3D Printing for Hobbyists: Your US Guide to Start in 2025

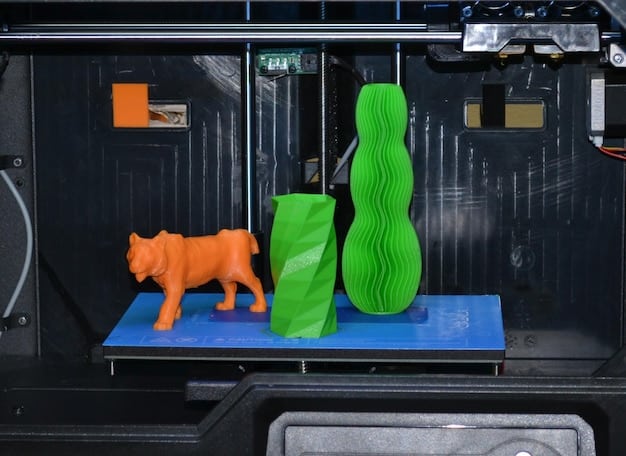

3D printing for hobbyists involves using additive manufacturing to create three-dimensional objects from digital designs, and this comprehensive guide provides insights and actionable steps for enthusiasts in the US looking to start their 3D printing journey in 2025.

Are you fascinated by the world of 3D printing and eager to jump in? This guide provides a comprehensive overview for 3D Printing for Hobbyists: A Comprehensive Guide to Getting Started in the US in 2025, covering everything you need to know to start creating your own amazing projects.

What is 3D Printing and Why Start in 2025?

3D printing, also known as additive manufacturing, turns digital designs into tangible objects by layering materials like plastics, resins, and metals. It’s a revolutionary technology that’s become more accessible than ever, making it perfect for hobbyists. But why start in 2025 specifically?

In 2025, 3D printing technology is expected to be even more refined and affordable. 3D printers will likely be more user-friendly, with improved software and automated features. Furthermore, the availability of materials and online resources will be vast, making it an ideal time for beginners to dive in.

The Basics of 3D Printing Technology

Understanding the fundamentals is key. 3D printing relies on Computer-Aided Design (CAD) software to create digital models, which are then “sliced” into layers that the printer follows. The printer then deposits material layer by layer until the object is complete.

- CAD Software: Learn to use software like Tinkercad (beginner-friendly) or Fusion 360 (more advanced) to design your models.

- Slicing Software: Programs like Cura and Simplify3D convert your CAD design into instructions for the 3D printer.

- Materials: Common materials include PLA (biodegradable and easy to print) and ABS (stronger but requires more controlled temperatures).

Starting in 2025 gives you access to the latest advancements, ensuring a smoother and more rewarding experience. With the right tools and knowledge, you can bring your creative ideas to life.

Choosing Your First 3D Printer

Selecting the right 3D printer is a crucial step for any hobbyist. With numerous models available, it’s important to consider your budget, intended use, and level of experience to make the best choice.

For beginners, Filament Deposition Modeling (FDM) printers are often recommended due to their simplicity and affordability. Consider these factors when making your decision:

FDM vs. Resin Printers

FDM printers melt plastic filament to create objects, while resin printers use liquid resin cured by UV light. FDM printers are generally more affordable and easier to maintain, making them a better choice for newcomers.

Key Features to Consider

- Build Volume: The maximum size of objects you can print. Start with a smaller build volume and upgrade as needed.

- Print Resolution: Measured in microns, lower numbers mean finer details. A resolution of 100-200 microns is good for beginners.

- Heated Bed: Essential for printing materials like ABS that require a consistent temperature to prevent warping.

Investing in a reliable and user-friendly printer will set you up for success. Look for printers with good reviews and strong community support for troubleshooting and guidance.

Essential Tools and Software

Besides the 3D printer, having the right tools and software can significantly enhance your 3D printing experience. It’s not just about printing; preparation, post-processing, and design are all crucial.

Necessary tools range from basic hand tools to specialized software, each playing a vital role in creating high-quality prints. Consider the following essentials to build your toolkit:

Hand Tools and Accessories

A basic set of hand tools is crucial for removing supports, cleaning up prints, and making minor adjustments. These tools will help you refine your 3D printed creations and address any imperfections.

- Scrapers and Putty Knives: For removing prints from the build plate and smoothing surfaces.

- Flush Cutters: To neatly trim support structures and excess material.

- Sandpaper: For smoothing rough edges and refining surfaces.

Software for Design and Slicing

CAD (Computer-Aided Design) software is used to create 3D models, while slicing software prepares these models for printing. These programs are essential for bringing your ideas to life and optimizing the printing process.

Choosing the right tools and software can dramatically improve the quality of your prints and streamline your workflow. Experimenting with different software options can also help you discover the tools that best suit your design preferences and printing needs.

Understanding 3D Printing Materials

The choice of material significantly impacts the strength, flexibility, and appearance of your 3D printed objects. Understanding the properties of different materials is essential for achieving the desired results.

Different materials offer unique characteristics that make them suitable for various applications. Starting with PLA, which is easy to print and biodegradable, is a great way to begin your 3D printing journey. As you become more experienced, you can explore other materials to expand your capabilities.

PLA vs. ABS: Which One to Choose?

PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are the two most common 3D printing materials. PLA is biodegradable, easy to print, and emits a minimal odor. ABS is stronger and more heat-resistant but requires a heated bed and good ventilation.

Exploring Other Materials

- PETG: Combines the best qualities of PLA and ABS—easy to print and more durable than PLA.

- TPU: A flexible material ideal for creating rubber-like parts, such as phone cases or gaskets.

- Nylon: A strong and durable material that can withstand high temperatures and stresses.

Choosing the right material is essential for achieving the desired properties in your 3D printed objects. Experiment with different materials to discover their unique characteristics and applications, and remember to follow manufacturer guidelines for optimal printing results.

Safety and Best Practices

Ensuring a safe and efficient 3D printing environment is crucial for avoiding accidents and producing high-quality prints. Establishing good habits early on will help you enjoy this hobby safely and effectively.

From proper ventilation to careful handling of materials, there are several key practices to consider. Adhering to these guidelines not only protects your health but also improves the longevity and performance of your 3D printing equipment.

Ventilation and Air Quality

3D printing can release volatile organic compounds (VOCs) and ultrafine particles, so good ventilation is essential. Ensure your 3D printer is in a well-ventilated area or use an enclosure with a filter. This helps to minimize exposure to potentially harmful emissions.

General Safety Tips

Following these safety precautions will help you create a secure and reliable 3D printing workspace.

- Keep Your Workspace Clean: Regularly clean your 3D printer and surrounding area to prevent the buildup of dust and debris.

- Don’t Leave the Printer Unattended: Supervise your 3D printer during operation to quickly address any issues.

By prioritizing safety and adhering to best practices, you can ensure a positive and rewarding 3D printing experience. A safe environment leads to consistent results and a more enjoyable hobby.

Finding Inspiration and Projects

One of the most exciting aspects of 3D printing is the endless possibilities for creating unique and personalized items. Whether you are a beginner or an experienced hobbyist, there are countless projects and ideas to explore.

Many online platforms and communities offer a wealth of designs, tutorials, and inspiration to fuel your creativity. Consider the following resources to kickstart your 3D printing journey and discover exciting new projects.

Online Design Repositories

Websites like Thingiverse, MyMiniFactory, and Cults3D offer vast libraries of 3D models that you can download and print. These platforms provide access to user-created designs, ranging from simple household items to intricate artistic creations.

Project Ideas for Beginners

- Phone Stands: A simple and practical project to learn the basics of 3D printing.

- Cable Organizers: Keep your cables tidy with custom-designed organizers.

- Personalized Keychains: Create unique keychains with your name or initials.

Exploring online design repositories and trying out beginner projects is a great way to develop your 3D printing skills and discover new ideas. Don’t be afraid to experiment and let your creativity guide you!

Maintaining and Upgrading Your 3D Printer

Proper maintenance and timely upgrades can significantly extend the life of your 3D printer and improve its performance. Regular care ensures consistent print quality and prevents common issues.

Keeping your printer in good condition involves routine cleaning, lubricating moving parts, and replacing consumable components. Additionally, upgrading certain parts can enhance functionality and expand your creative possibilities.

Regular Maintenance Tasks

Regular maintenance is essential for keeping your 3D printer running smoothly. Consistent cleaning and lubrication will help prevent breakdowns and ensure optimal print quality.

When to Consider Upgrades

- Improved Extruder: Upgrading to a more reliable extruder can improve filament feeding and print accuracy.

- Auto Bed Leveling: Automated bed leveling systems save time and ensure consistent print adhesion.

- Upgraded Motherboard: A new motherboard can provide faster processing speeds and advanced features.

By performing regular maintenance and investing in strategic upgrades, you can maximize the lifespan and capabilities of your 3D printer. These efforts will lead to more consistent results and a more enjoyable 3D printing experience.

| Key Point | Brief Description |

|---|---|

| 🖨️ Printer Choice | Select an FDM printer for ease of use. |

| 🛠️ Essential Tools | Gather tools like scrapers, cutters, and sandpaper. |

| 🧪 Material Selection | Start with PLA for easy and safe printing. |

| 💡 Safety First | Ensure good ventilation and supervision during prints. |

FAQ

▼

FDM (Fused Deposition Modeling) printers are generally recommended for beginners due to their ease of use and affordability. Look for models with good reviews and strong community support.

▼

You’ll need CAD (Computer-Aided Design) software for creating models and slicing software to prepare the model for printing. Tinkercad and Cura are great options for beginners.

▼

Yes, but it’s important to take precautions. Ensure good ventilation to minimize exposure to emissions, and always supervise the printer during operation to address any issues promptly.

▼

Common materials include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG, and TPU. PLA is a great starting point due to its ease of use and biodegradability.

▼

Explore online repositories such as Thingiverse, MyMiniFactory, and Cults3D to find a wide range of 3D models. Start with simple projects like phone stands and keychains.

Conclusion

Embarking on the journey of 3D printing as a hobbyist can be incredibly rewarding. By understanding the basics, choosing the right equipment, and prioritizing safety, you can unlock a world of creative possibilities. As 2025 approaches, the technology continues to evolve, making it an ideal time to explore the potential of 3D printing.

![Quantum Computing for Beginners: A US Geek's Guide [2025] Quantum Computing for Beginners: A US Geek's Guide [2025] - Cover Image](https://dorama2you.com/wp-content/uploads/2025/06/dorama2you.com_3_1749769492_79bdbcc1_cover-360x180.jpg)